Hey guys i just recently posted a thread about rebuilding a motor but i forgot to ask how to do a 2.3 oil pump swap. How and what do i need to do it? and is it really better than the 2.4 pump? whats makes it better?

that looks really confusing and i dont think i wanna do that ill stick to the 2.4 oil pump

It's a lot of work, and will make even experienced machinists @!#$ bricks as they drill. Not for the faint of heart.

Worth it in the end though.

Paying someone to install parts and bragging about it being fast, is like watching someone bang your wife and being proud to raise their kids.

i mean im trying to grow a set lol its just that i only have one short block and i dont wanna pour a lot of money into this motor just for it to eff up if i do it wrong ya know? but how does it help out a ton?

Increases oil flow and gets rid of the possibility of cavitating the oil at high rpms, which the 2.4 oil pump just loves to do. If you have a short block already, do the pump swap before having it hot tanked, decked and bored/honed. That way if you junk it you are out as little money as possible.

Paying someone to install parts and bragging about it being fast, is like watching someone bang your wife and being proud to raise their kids.

would a 2.3 block fit a 2.4 head? because i can get a short block 2.3 instead of converting it

Time to start searching, this info has been gone over and over.

Paying someone to install parts and bragging about it being fast, is like watching someone bang your wife and being proud to raise their kids.

i think imma just give the 2.3 oil pump swap a shot nothing ventured nothing gained right?

i'd get a machine shop to do the work for you... its not that bad of a swap...

It's basically bolt on when you have a shop do it for you, lol

Paying someone to install parts and bragging about it being fast, is like watching someone bang your wife and being proud to raise their kids.

so basically take it to my motor specialist and have him do it? on average how much does it cost for a machinist to do it?

If your confident with a drill it seems time consuming but not hard as long as the pilot holes are straight. I will be doing this to a 95 2.3 block just to see if I can.

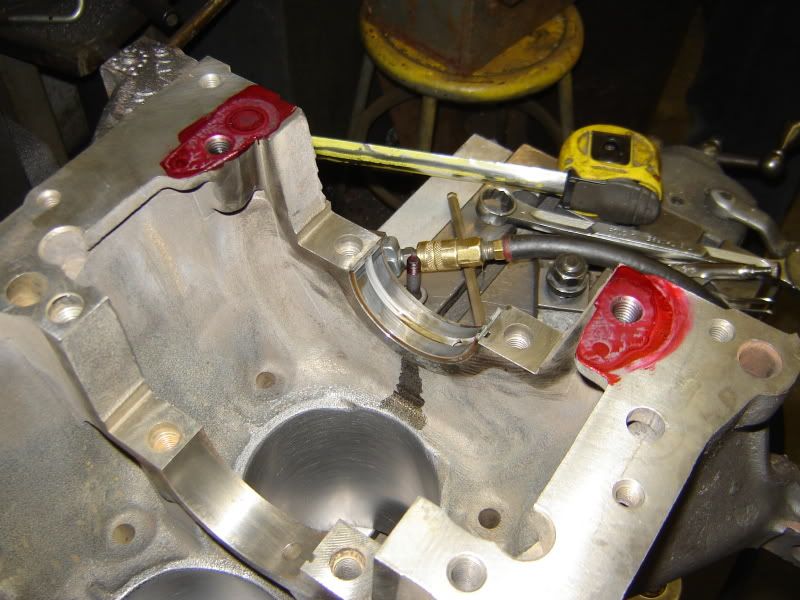

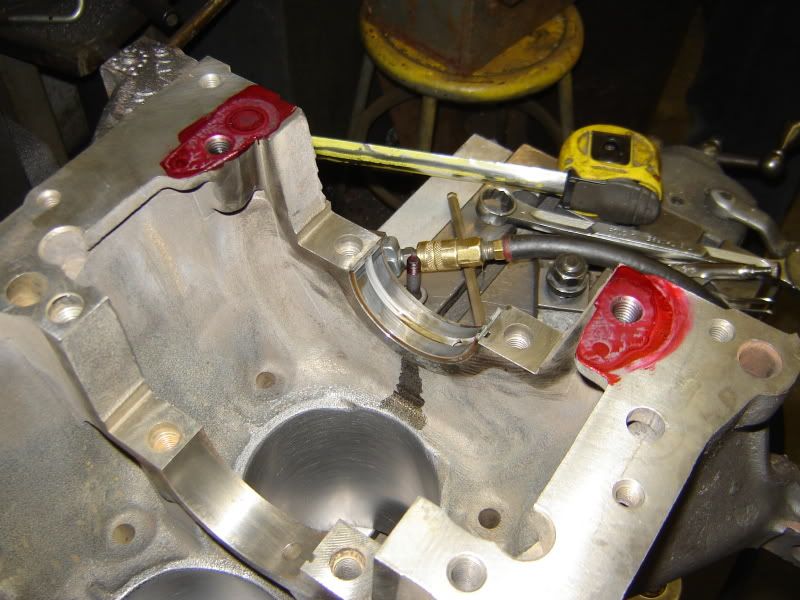

so basically all your doing is making a new oil passage and making new mount holes and plugging the old inserts

yep pretty much drill drill drill then you have to plug a few holes tap and plug one hole you drill in the corner of the block to connect the hole from the pump to the oil passage in the block..

after looking at the photos it doesnt look to tough it just looks real tedious

my guy charged $740 on my first one but that also included a line hone, block decking, block cleaning, relocation block and pick-up, pan machining, main cap braces, and custom arp main studs. i provided the oil pump, windage tray, and crank gear.

he did it the hard way though where you press a tube into the block to create the passage. in some ways its easier if you have the machines, etc. some say it leaks this way but im not worried as he's done it several times to roundy round cars that run for years without issue.

most shops will just tell you they charge by the hour and will not have a set time for the work. if you find a shop thats done one before then i wouldnt pay any more than $200. but if you get one that has not... be prepared to pucker up the butt.

as for you're question of doing a 2.4 head on a 2.3 block, yes.. you can but you're compression ratio is gonna be dropped unless you deck the crap out of ur head and run a thinner head gasket.

Edited 1 time(s). Last edited Wednesday, December 07, 2011 5:26 AM

Come join us over on the Olds Quad 4 and Twin Cam Facebook group!

Come join us over on the Olds Quad 4 and Twin Cam Facebook group!

Honestly if you're good with a drill it's pretty simple to do on your own. Having a rotating engine stand helps with some of the angles. Tapping some of the holes was a little challenging as theyre not all straight but you can get the whole thing done in an hour or 2 if you know what you're doing. You can destroy a block if you're not careful though. It's intimidating and a bit of a challenge but worth it.

Edited 1 time(s). Last edited Wednesday, December 07, 2011 10:30 AM

I did mine on my Bridgeport. You should go out and buy a 3 phase generator and a mill, it'll be much easier

Paying someone to install parts and bragging about it being fast, is like watching someone bang your wife and being proud to raise their kids.

i also seen on the jbody performance website they have a high flow 2.4 oil pump any ideas on how well that one does?

It's not hard if you know how to drill in a straight line. And you don't have to redrill the pump mounting holes, only the oil feed holes.

The only MOUNTING holes you should be drilling/tapping are the windage tray ones. Honestly, the FAQ makes it sound way more complicated than it is. The hardest part is getting a set of bolts to bolt down the pump, since they're discontinued. Which sucks for me because I lost my previous set and need more, but have no way of getting them.

Earl McNulty wrote:i also seen on the jbody performance website they have a high flow 2.4 oil pump any ideas on how well that one does?

Essentially it's BS, all it is is a Mellings replacement pump that has never been proven to pump any better than the stock 2.4 pump.

Also, don't order anything from that website, you will never see your part or your money again.

Thrice . wrote:It's not hard if you know how to drill in a straight line. And you don't have to redrill the pump mounting holes, only the oil feed holes.

The only MOUNTING holes you should be drilling/tapping are the windage tray ones. Honestly, the FAQ makes it sound way more complicated than it is. The hardest part is getting a set of bolts to bolt down the pump, since they're discontinued. Which sucks for me because I lost my previous set and need more, but have no way of getting them.

1. Bring ball peen hammer to junkyard

2. Find old quad

3. Smash brittle cast aluminum oil pan with hammer

4. Unbolt oil pump

They will appreciate it if you catch the oil in a pal though... haha

Paying someone to install parts and bragging about it being fast, is like watching someone bang your wife and being proud to raise their kids.

Transporter7220 wrote:Earl McNulty wrote:i also seen on the jbody performance website they have a high flow 2.4 oil pump any ideas on how well that one does?

Essentially it's BS, all it is is a Mellings replacement pump that has never been proven to pump any better than the stock 2.4 pump.

Also, don't order anything from that website, you will never see your part or your money again.

This is a very true statement