well I hooked up the tru-boost boost controller and I'm having problems with it. for the hahn kit signal hoses go from the turbo housing to the wastegate and FPR correct?

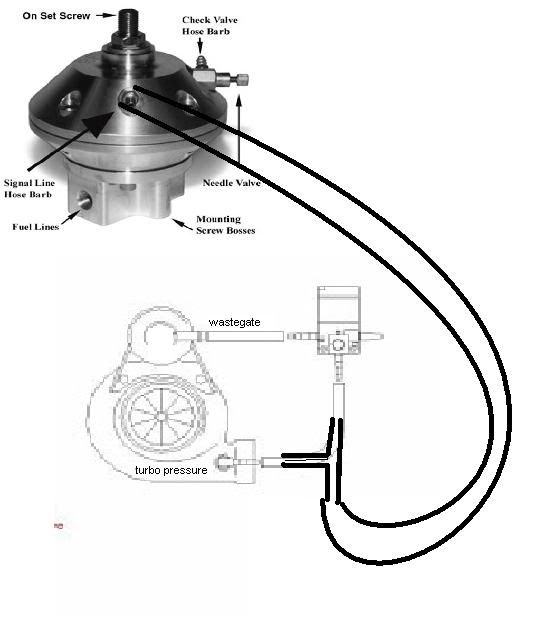

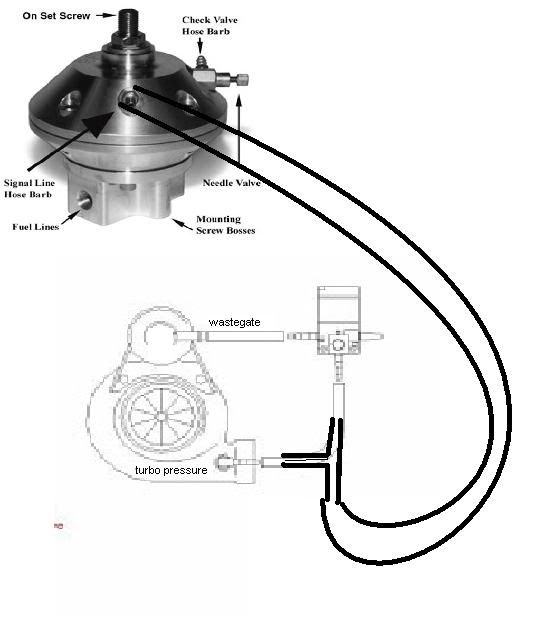

This is how I hooked it up

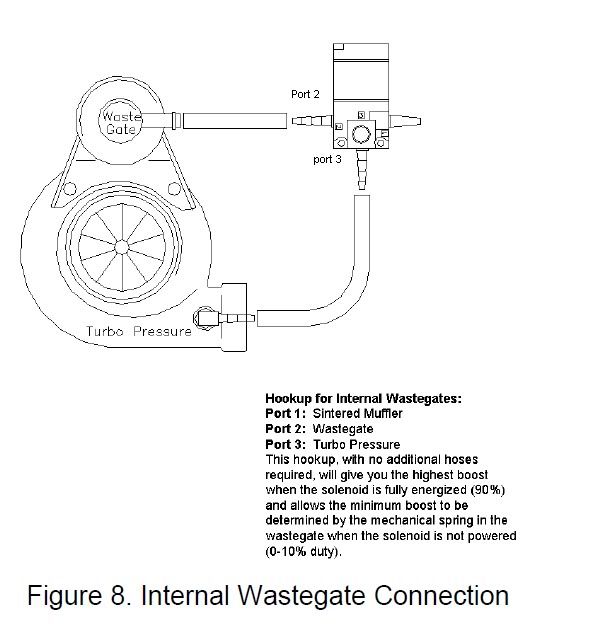

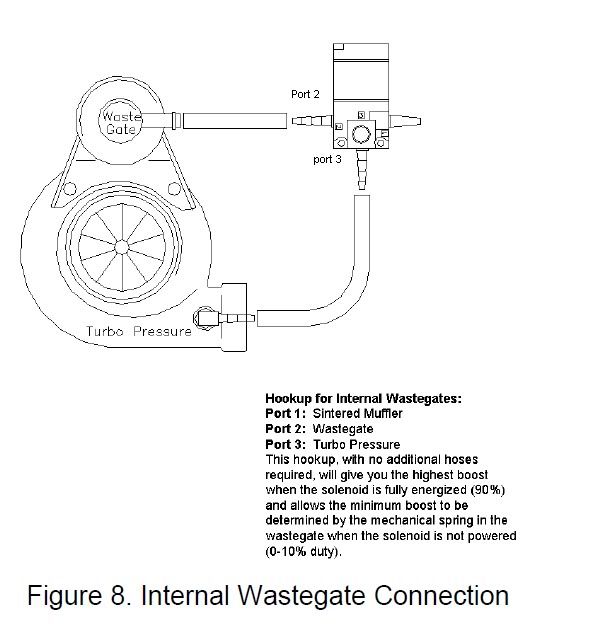

This is what AEM wants

When energized, ports 1 & 2 are connected, when de-energized, ports 2 & 3 are

connected.

problem is if I adjust duty cycle on my controller I lean out the car and boost level does not rise. I figured I'm screwing up the signal to the fpr but not sure how to hook it up otherwise. Right now the controller is just turned off until I figure this out.

Thanks

You do not wish to share the signal for the fuel regulator with a boost control solenoid. The boost control solenoid bleeds off boost pressure in this line, and will play havoc with the signal to the fuel regulator. Always run them on completely separate hoses, from separate sources.

Bill Hahn Jr.

Hahn RaceCraft

World's Quickest and Fastest Street J-Bodies

Turbocharging GM FWD's since 1988

www.turbosystem.com

As for the function of the boost controller, try it again once you separate the signal hoses as I've described. As the fuel regulator also has a bleed, it should not be shared with the wastegate signal hose.

Bill Hahn Jr.

Hahn RaceCraft

World's Quickest and Fastest Street J-Bodies

Turbocharging GM FWD's since 1988

www.turbosystem.com

Okay so where should I get my signal for the fpr? Should I run that off of manifold pressure or should I get the pressure for the solenoid from the manifold

FPR to comp housing, WG to intake manifold.

Bill Hahn Jr.

Hahn RaceCraft

World's Quickest and Fastest Street J-Bodies

Turbocharging GM FWD's since 1988

www.turbosystem.com

Will that affect the bov or boost readings in anyway

Can you be more specific? I didn't see your BOV mentioned here, nor do I know what you mean by "boost readings".

Bill Hahn Jr.

Hahn RaceCraft

World's Quickest and Fastest Street J-Bodies

Turbocharging GM FWD's since 1988

www.turbosystem.com

Well the bov signal hose is connected to the monifold, also where the gauge gets its vac and boost psi from could having the ssolenoid T'd in affect those

Here's your best bet.

Do not share either the boost-controller/wastegate or FPR signal hoses with any other component, including each other. As they both bleed signal, they affect the actual pressure in their respective signal hoses, and that can have a negative affect on other components.

Bill Hahn Jr.

Hahn RaceCraft

World's Quickest and Fastest Street J-Bodies

Turbocharging GM FWD's since 1988

www.turbosystem.com

Hahn turbo here as well with a Tru-Boost.

Basically what you are trying to do is put the boost solenoid inline and before the wastegate.

I know some people might disagree with me here, but the setup has been working great for me.

Compressor -------> FMU.

Intake manifold ----- TEE ----- BOV and Boost Solenoid Port 3.

Solenoid Port 1 --------> Wastegate.

I ended up buying a brass tee. The hose that runs between the intake mani and the BOV, I cut it in half, put the tee in there, and ran the extra line to the boost solenoid. Next you run from the other port of the boost solenoid to the Wastegate.

This info came from an e-mail from hahn tech support a while ago, and it's been working great ever since.

Also, if you plan on boosting it any higher, I'd recommend HP Tuners, bigger injectors, and a built bottom end.

I was reading great AFR's (high 11's), on a Racetronix pump, and 10psi. Blew a ringland on the piston, and had to rebuild.

Just my $.02

That was my plan thanks, what size injectors were you running?

I was running the 32lb injectors that came with the Hahn Stage 2 Kit.

There are other threads on the subject. GM reduced the size of the top ringland for emissions reasons. So in relation, it definitely decreased the integrity of the stock pistons under heat and pressure.