thanks alot bro. I'm going to take this advice and run with it.

**changes are here**

we use sb rocker studs in our race motors, we just take a 3/8 tap and go into the hole and put an arp long thread stud in, it makes the top end completely adjustable no questions on pushrod length

Quote:

we just take a 3/8 tap and go into the hole and put an arp long thread stud in

You're talking iron heads? The head above uses a threaded stud with a 10mm thread and a shoulder which is almost 12mm IIRC. It's strong, but doesn't work with taller aftermarket roller rockers.

-->Slow

no, the same head he has. the aluminum heads we make it so we can adjust the top end.

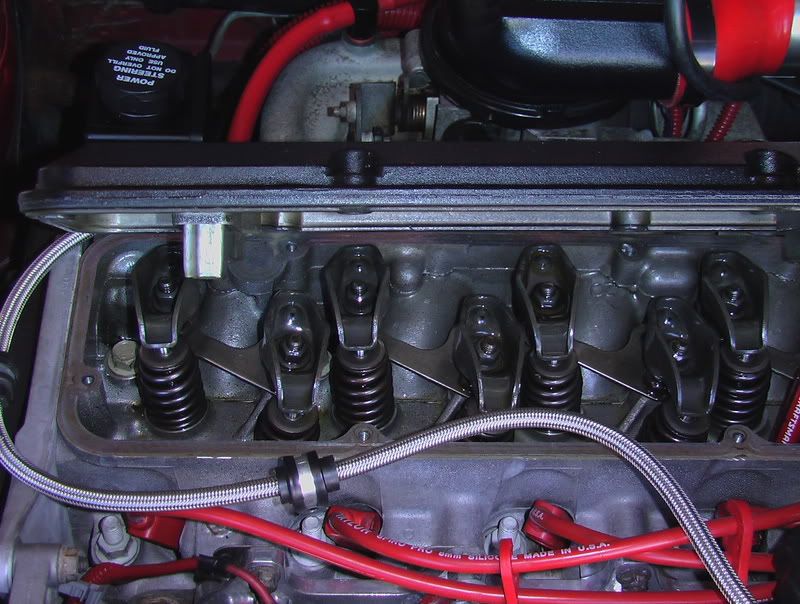

stock studs

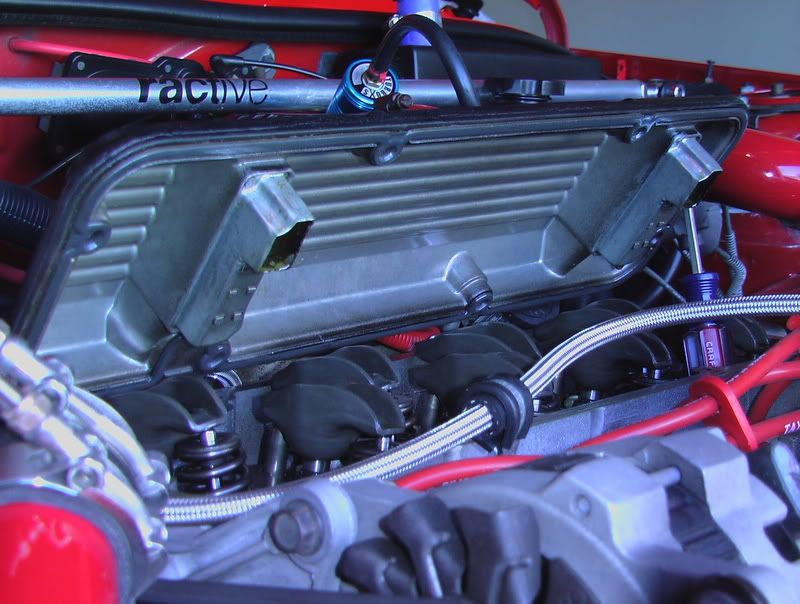

sb studs

o wow, did not know about screw in studs, that will be so much easier haha

Well, I guess there's no problem with the 3/8 studs pulling out of the 10mm holes. They're loose enough that I probably wouldn't have tried it.

2.8, 3.1 engines originally had 10mm screw in studs and adjustable rockers. If you're racing with "no roller rocker" rules you can find those parts fairly cheap in junkyards up and down the east coast. The 3100 switched to roller fulcrum rockers with positive stop bolts instead of studs.

I've about given up on finding 10mm posi-lock rocker nuts. I'm probably going to end up using standard 10mm locknuts with spacers in order to use the LT4 rockers. And here I thought I'd be saving money by not using the 10mm to 3/8 conversion studs. <sigh>

-->Slow