I know some of this has been covered but I couldnt find direct answers so I have a few questions.

For those of you that have drilled and tapped your ld9 oil pan for the return fitting, who has had problems with it leaking or anything?

When using a 10-an fitting, what size drill bit and npt tap is needed?

Id like to see any pics of fitting placement on auto 2.4 setups, I thought had some saved and cant find them on here.

Thanks, any input is helpful.

i know when miller performance welded my oil pan for the 2.3 oil pump he just tapped my pan for a 1/2" npt and then i got a 1/2" npt to -10 an fitting. both side male and it works well. as far as location i can only show you my location which is for a manual

-- MyZcar

I'd really consider having a fitting welded to your pan, rather than drilling/tapping it.

Yea I know welding a fitting would be much better, but I just want it temporarily and want to see how people's have held up with it just tapped in. I plan to start a motor build right after turbo, and want to have my pan modded for the 2.3 pump swap and ill just have the fitting welded on then which I already have. Its hard to find and good places around here that can weld aluminum otherwise Id prolly just have the fitting welded in.

Ill look for a 10an to 1/2 fitting, but does anyone know what size drill bit and npt tap would be needed for just the 10an fitting?

icemike89 wrote:Yea I know welding a fitting would be much better, but I just want it temporarily and want to see how people's have held up with it just tapped in. I plan to start a motor build right after turbo, and want to have my pan modded for the 2.3 pump swap and ill just have the fitting welded on then which I already have. Its hard to find and good places around here that can weld aluminum otherwise Id prolly just have the fitting welded in.

Ill look for a 10an to 1/2 fitting, but does anyone know what size drill bit and npt tap would be needed for just the 10an fitting?

again i wish i knew the answer to the drill bit size but i dont. as far as welding aluminum for the bung and 2.3 oil pump mod i would recommend

Miller Performance to anyone. He did extremely good work and his turn around time was amazing. He had it all done in two days and that includes powdercoating. also he will put the bung where ever you would like it located. he may kno the drill and npt size for the - 10 an.

here is his profile

-- MyZcar

Yea I plan to get a pan from him when I build the motor and do the pump swap, great price for all that you get. But, Im still gona be turbo on a stock higher mileage motor for a while and if the motor decides to let go I wouldnt want to damage that nice pan; so Im looking to drill/ tap mine for now.

Soo any pics from anyone? If not Ill have to start hunting through registries/old posts

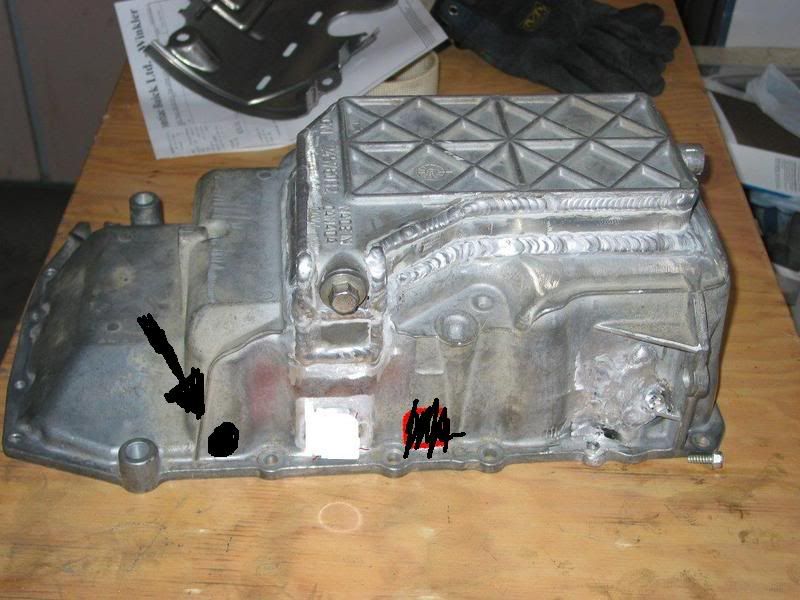

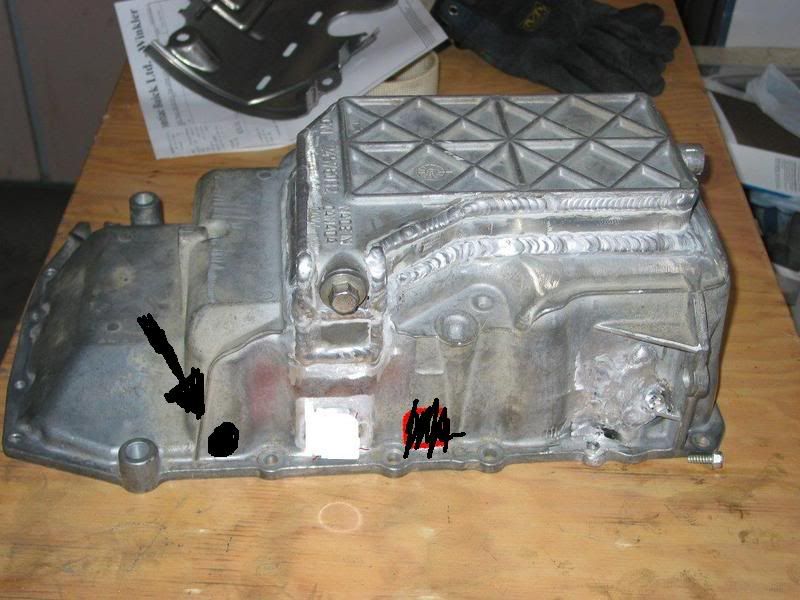

I dont kno if that helps or not since i have a manual. i had mine put where the red box is and todd at miller was thinking of putting it where the white box it. I imagine one of the two locations should work.

-- MyZcar

Ok I did a little googling and research .Found to use a 45/64" drill bit, and a 1/2"-14 npt tap will work for a 10-an fitting. As said this will be only temporary until I get a miller pan or one modded for the pump swap and a bung will be welded on.

Thanks for the pic man, Im gona search some old posts from some of the auto ld9 builds I know of.

after turbo? ditching the supercharger already? i can kinda explain how we did jeffs return line.

thats where we tapped his.... the auto trans is a bitch..... we used that 45 degree -10 to 1/2 npt, and we had to point it toward the passenger side, and up a lil, then the line ran around the tranny................... if that makes sense.. it was a pain, but it works...

pm me if ya need help, maybe i can get jeff over and we can take some pics of it

Cool thanks man. Yea I decided to ditch the sc when it started making some crazy ass noise, plus I came across alot of turbo stuff off an auto z so I picked it up. I just about have everything so it will be happening very soon.

Anyways, Ive decided to use a bulkhead fitting instead of tapping the pan. Thanks for the info Ben, I figured it was somewhere in that area with the auto trans but I was actualy gona ask Jeff if I didnt get an answer haha.

Mike i think you should just do the oil pan mod yourself, me and my dad did the extension of the pan ourself in about 1/2 hour, theres no need to pay crazy money for a miller performance one when you can do it yourself easily. This is when you build your motor

37/64" drill bit for a 10an fitting. I eventually welded a aluminum bung in mine because the drill / tap / and fitting kept leaking. After the welded fitting it never leaked once...

Windy City TurboZ

Yea I just went ahead and bought a 10an bulkhead fitting, which from what Ive seen done is a 7/8" drill bit. Ill have the bung welded in later, hopefully I wont have any problems with having a nut inside the oil pan