Ok I am going to put somewhere between 6.5 psi on my eco I am going to buy the begi fmu, what do you guys recomend for injectors and what else is a must for fuel system upgrades...

I seen the fuel pump on the turbo list, but am I really going to need it...

I also was wondering about the MSD DIS-2 needed or not...

thats really not a whole lot of boost, correct me if im wrong but stock fuel system should be able to handle it. idk for sure cuz im just getting into the boosted scene.

horsepower is the force that determines at what speed you hit the wall, torque is the force that determines how far you take the wall with you after you hit it.

Stock fuel system will be fine....

i run 13psi on a stock fuel system..

12.33 @ 111.67 mph [Oct 2009]

Dyno'd on 08/02/09 - Mustang Dyno:

327.6 WHP 333.6 WTQ [10.1 AFR]

the begi adjustable fmu. Thats what i ran off of for a good while. I had the hahn 32 pound injectors. I ran them all the way up to 15 psi. Just after you get bossted your going to want more boost. Just be careful get you a wideband!! dont blow it up like i did!!!

BOOSTED BABY wrote: Just be careful get you a wideband!! dont blow it up like i did!!!

I am already on it no worries...

02 silver cavy wrote:thats really not a whole lot of boost, correct me if im wrong but stock fuel system should be able to handle it. idk for sure cuz im just getting into the boosted scene.

correct me if I am wrong but cant I still up the boost with a boost controller ??? I know you cant make it go any lower but I thought you can raise the boost .... A wastegate is only a pressure regulated throttle valve...

..I hope the responses to this thread aren't serious

DaFlyinSkwir(LS61) /PJ/ OEM+ wrote:..I hope the responses to this thread aren't serious

Well than what do you think ??? And what responses ???

Larger fuel injectors and a way to control fuel delivery.

DaFlyinSkwir(LS61) /PJ/ OEM+ wrote:..I hope the responses to this thread aren't serious

PJ has basically proven that stock injectors are maxxed out on the stock engine when you try to tune in a decent AFR. I've seen 90% duty cycles on my car with bolt ons. Do yourself a huge favor, get at least 440cc/min (ford green tops) so that you don't have to worry about upgrading injectors for a while.

Also it helps to know what turbocharger you'll be running. You know how it goes right? A t3 super-60 will not flow the same air as a GT3582r at the same pressure...

Thank you old school ....

I have not been around long enough to know all of this stuff... I will be running a t3 super-60 external w/g with a 6.5 spring... So Ford green tops are a good injector to use, are the plugs the same... I will make note that I have the 02 fuel rail... So will I need a new fuel rail also... What is a good afpr to use ??? I already have a begi fmu, and am getting an innovate standalone wide band...

Sorry for all the noob questions but how else am I going to learn... That's what the forum is for right to learn...

I tried to post on the stickies first but no one looks up there ...

If you have an 02 fuel rail LSJ injectors will work perfectly (36 or 38 lb injectors, I forget)

Speaking of which I just joined a cobalt ss forum just for that reason... So I am going to go with those injectors they should be good, plus they are cheap... Now all I need is an afpr, which is a good one and where can I get it...

Does your begi fmu have a screw at the top? if so that is also a fpr.

22ECO [DesertTuners wrote:]Speaking of which I just joined a cobalt ss forum just for that reason... So I am going to go with those injectors they should be good, plus they are cheap... Now all I need is an afpr, which is a good one and where can I get it...

i know a guy who has a set of cobalt ss injectors, probably for sale. goto www.gmscf.com and look up JNetSS.

12.33 @ 111.67 mph [Oct 2009]

Dyno'd on 08/02/09 - Mustang Dyno:

327.6 WHP 333.6 WTQ [10.1 AFR]

BOOSTED BABY wrote:Does your begi fmu have a screw at the top? if so that is also a fpr.

Yes the begi fmu is adjustable

uh yea i was serious. Im hitting 13psi and still have a stock fuel system, IE stock pump, stock FPR

12.33 @ 111.67 mph [Oct 2009]

Dyno'd on 08/02/09 - Mustang Dyno:

327.6 WHP 333.6 WTQ [10.1 AFR]

injectors aren't considered part of the stock fuel system?

I hate to argue semantics, but when you're trying to give advice its sort of important... upgraded injectors is not a stock fuel system.

Edited 1 time(s). Last edited Tuesday, May 12, 2009 9:31 PM

First Sweetness where did you get that hood????

So are the cobalt ss injectors good enough?? Add a afmu and call it good???

This turbo stuff is not cheap, well doing it the right way isn't cheap... After I get the fuel system squared away its off to tuning and monitoring stuff next...

if you want to argue semantics then you are probably right, injectors would be considered part of the fuel system, but what i was assuming he was asking about was the fuel pump and fuel pressure regulator and also assumed he knows he would need new injectors since he asked what injectors people are running, so when i meant by stock fuel system was stock pump and stock fpr.

i use 42# injectors with my supercharger setup, not sure how much different it would be with a turbo since im sure 7psi on my blower and 7psi on a turbo can be different in terms of airflow..

12.33 @ 111.67 mph [Oct 2009]

Dyno'd on 08/02/09 - Mustang Dyno:

327.6 WHP 333.6 WTQ [10.1 AFR]

SweetnessGT wrote:22ECO [DesertTuners wrote:]BOOSTED BABY wrote:Does your begi fmu have a screw at the top? if so that is also a fpr.

Yes the begi fmu is adjustable

Um, an FMU *is* a rising-rate FPR, by definition.

If what you're trying to suggest, Boosted Baby, is that he can use it to replace his stock FPR, yeah... no. That is not the function of an AFMU like the BEGI unit.

That top allen screw is the boost-onset screw. It is not meant to tune your static fuel pressure whatsoever. The side screw is the ratio screw for the disc. If you do not know what the boost-onset screw is or why Corky Bell designed its function to exist, then you weren't using your BEGI AFMU right.

Agreeing with PJ here - are 80% of you guys serious about your responses? Really? The stock Ecotec fuel system is fine? Yikes...

-Chris-

Im not going to agrue with you at all but what i have is exjactly what you are talking about. The TOP ALLEN screw is used to adjust IDLE FUEL PRESSURE. So YES you can use that to REPLACE your stock fuel pressure reg.

BOOSTED BABY wrote:SweetnessGT wrote:22ECO [DesertTuners wrote:]BOOSTED BABY wrote:Does your begi fmu have a screw at the top? if so that is also a fpr.

Yes the begi fmu is adjustable

Um, an FMU *is* a rising-rate FPR, by definition.

If what you're trying to suggest, Boosted Baby, is that he can use it to replace his stock FPR, yeah... no. That is not the function of an AFMU like the BEGI unit.

That top allen screw is the boost-onset screw. It is not meant to tune your static fuel pressure whatsoever. The side screw is the ratio screw for the disc. If you do not know what the boost-onset screw is or why Corky Bell designed its function to exist, then you weren't using your BEGI AFMU right.

Agreeing with PJ here - are 80% of you guys serious about your responses? Really? The stock Ecotec fuel system is fine? Yikes...

-Chris-

Im not going to agrue with you at all but what i have is exjactly what you are talking about. The TOP ALLEN screw is used to adjust IDLE FUEL PRESSURE. So YES you can use that to REPLACE your stock fuel pressure reg.

In reference to the 2025 unit, clone / whoever the hell made it

X2 The top screw sets the idle fuel pressure. It does this by setting the base upper position of the shim (Point at which most fuel is being returned = least rail pressure)

The needle valve controls the onset of the rise in fuel pressure. If you want to decrease the ratio at which the FMU adds fuel per 1lb of boost then you need to add a line restrictor to the vacuum line.

Using the needle valve and various size restrictors you can pretty much achieve any onset rate and ratio that you want.

I love how people somehow think this unit is magic or difficult to understand, its the simplest damn concept in the world.

___________________________________________________________________

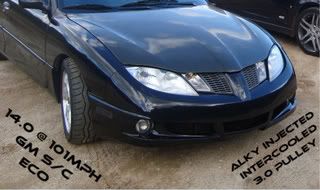

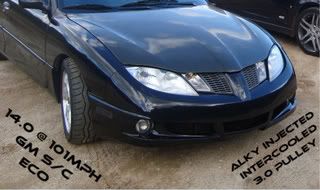

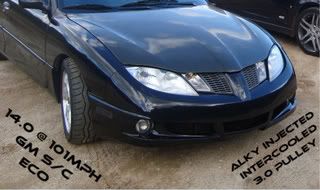

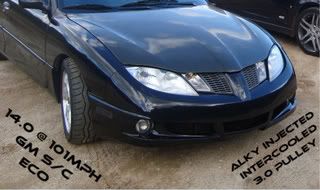

Hahn Stage II - Mitsu TD06-20g |3" Turbo-back Exhaust | 61mm Bored TB |

HP Tuners | Innovate WB02 | Spec Stage 3 | Team Green LSD | TurboTech Upper | Full Addco Sways | Sportlines & Yellows |