Okay so here is my question and problem. I bought the racetronix fuel pump setup for my 02 ecotec cavalier, and the racetronix fuel pump comes with a 3/8 feed line. The barb fitting/nipple on the top of my sending unit that the feed line attaches too is for a 5/16 line. So my question is did you just tighten the hose clamp as tight as you could or did you go about it another way? I just tightened it up but im starting to think that did not get it tight enough and the fuel is spraying out at that connection point. Reason being is i can not get pressure to go above 28psi when the car is idling. When i pull the feed line off and put the feed line in a milk jug gas seems to just run out instead of spray when i turn the key on. The only other thing that i can think that it could be a is pinched feed line. But the part that is really baffling me though is when i started the car up the first time after installing the pump i had 80 psi of pressure idling and then backed it down to 50psi on the BEGI FMU (what im using for a regulator and has always worked fine) and the let the car idle for a half hour with the pressure holding just fine at 50psi. Starting it every time since then i have had the problem stated. Any input is very much appreciated

If your interested in custom aluminum tilt wheel levers hit me up!

I double clamp'd it. One screw clamp and one squeze clamp.

yeah i didn't like it when i put it in that way but when you get a new toy sometimes you get in a hurry.

If your interested in custom aluminum tilt wheel levers hit me up!

Maybe check your fuel filter?

I just installed one this week in my 03. I dont think i am having any problems. There is also one in the turbo car. Never had any problems...

I only have about 100 miles on this filter, but the car has been sitting for a year so maybe i will go ahead and change it again. So everyone seems to just clamp the supplied 3/8 hose over the 5/16 nipple?

If your interested in custom aluminum tilt wheel levers hit me up!

Whats up Burkett?!?!? Long time no talk....

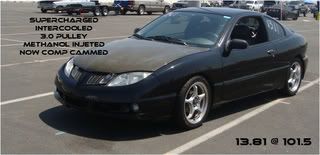

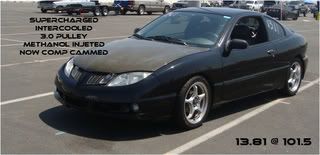

P&P Tuning

420.5whp / 359.8wtq

not much just trying to get this pos up and running again

If your interested in custom aluminum tilt wheel levers hit me up!

To test the pump flow rating (walbro 255 LPH is the rating). So do some conversion and figure out gallons per minute - I think it's about 1.2 gpm. An open line should not really spray since you have little or no resistance, but will put out close to this volume. So if you're getting 1/2 gallon in 30 seconds the flow is good.

If you're not getting pressure clogged filter could be it but an '02 only sitting for 1 year seems sort of strange. If you clamped that 3/8" down to 5/16" be sure you didn't crack it. Could be possible that at 80psi you popped off the hose/clamp. Wish I could be of more help but I have an 98 sunfire w/ 3/8" feed line :-)

Careful...just flowing fuel out of the fuel pump module in the fashion you describe will quickly drain the module, as it's designed to fill much more slowly than a gallon per minute. As this is far in excess of what the engine could ever consume, and you are not testing against pressure, this form of test is largely inaccurate.

A better approach is to run the car hard on the street, track, or dyno, and monitor fuel pressure. Should the pressuer drop off at high demand, you then know you have a supply problem worth diagnosing.

Bill Hahn Jr.

Hahn RaceCraft

World's Quickest and Fastest Street J-Bodies

Turbocharging GM FWD's since 1988

www.turbosystem.com

Careful...just flowing fuel out of the fuel pump module in the fashion you describe will quickly drain the module, as it's designed to fill much more slowly than a gallon per minute. As this is far in excess of what the engine could ever consume, and you are also not testing against pressure, this form of test is largely inaccurate.

A better approach is to run the car hard on the street, track, or dyno, and monitor fuel pressure while you do so. Should the pressure drop off at high demand, you then know you have a fuel supply problem worth diagnosing.

Bill Hahn Jr.

Hahn RaceCraft

World's Quickest and Fastest Street J-Bodies

Turbocharging GM FWD's since 1988

www.turbosystem.com

Thanks for the help guys. But i think i know what the problem is now. I just need to drop the tank to verify it, but i think since this pump has the barb to run the factory venturi setup (all other walbros don't have this), im thinking that hose may have came off the pump causeing my problem. I will post back if that fixes it when i get the tank out.

Bill i took the car for a test drive just doing little second gear pull and fuel pressure did jump up to 60psi but it wasn't a climb to 60psi if that makes sense. I just dont like the fact of it idling with the fuel pressure so low even though it won't hurt anything idling and that i can't adjust it at all. Yeah i know the way i described to see what the fuel pressure looked like in a jug is my no means a way to check what i was flowing, but im possitive that when i had done this before fuel actually sprayed with some pressure instead of just kind of run out.

If your interested in custom aluminum tilt wheel levers hit me up!

The problem was what i thought it was. Venturi line came off the pump. I will put a clamp on the little SOB this time

If your interested in custom aluminum tilt wheel levers hit me up!

the exact same thing happened to me about a month ago

YEah it just sucked that i added 8 gallons of gas before it happened and i had to drop and intall the tank by myself

If your interested in custom aluminum tilt wheel levers hit me up!

OK. So what was happening is your module was emptying out from the open venturi hose, thus the inconsistent/low fuel pressure. I'll bet the pump was complaining a bit (whiny noise) when the pressure was low too.

Advice to all: be careful with this stuff, for you can trash out a new pump in a hurry if you allow it to suck air, not fuel.

Bill Hahn Jr.

Hahn RaceCraft

World's Quickest and Fastest Street J-Bodies

Turbocharging GM FWD's since 1988

www.turbosystem.com

What kind of a clamp did you end up using? I couldn't find one that would go that small and keep even pressure on the circumference of the line, so I had to get a little innovative..........

Well i ended up using a zip tie. But i made sure it would be okay to be soaked in gas for periods of time first before using it. IF i would have had some stainless wire i would have just wrappped that around it and twisted it with some pliers

If your interested in custom aluminum tilt wheel levers hit me up!

what I did with mine was clamped the clamp that is already on there tighter with a pair of pliers. I haven't had any problems yet and my fuel pressure is staying a constant 46psi